Projects

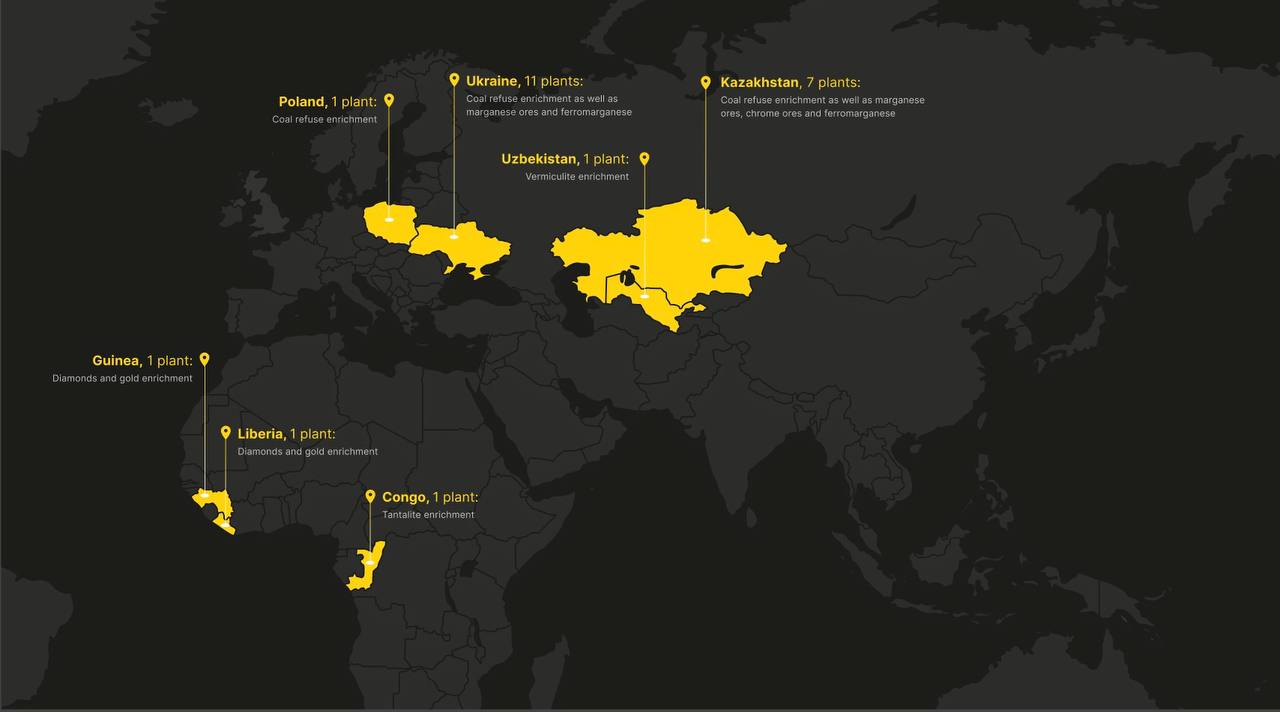

Gravicon’s modular plants are successfully operating in more than 7 countries, delivering efficient and environmentally responsible mineral recovery solutions across Africa, Central Asia, and Europe.

Global Network of Gravicon Plants

The map below shows all operational and completed Gravicon plants worldwide. Each point represents a modular beneficiation facility developed using our proprietary technology. These projects demonstrate the adaptability of Gravicon solutions across different materials, climates, and industrial conditions.

Gravicon Project Lifecycle

The following stages illustrate the full path of cooperation between Gravicon and the client — from the first sample to full-scale production.

Sample Submission

Client provides a representative sample of the material or tailings.

This defines the project’s starting point and economic potential.

Duration 1 week

Beneficiation Test

The sample is analyzed using Gravicon’s proprietary technology.

We confirm recovery rates and concentrate quality.

Duration 1 week

Commercial Proposal

A detailed offer is prepared with all key parameters.

Includes performance guarantees and technical data.

Duration 2 weeks

Technical Alignment

Together we finalize project scope and specifications.

All details are aligned before project launch.

Duration 1 week

Contract Signing

A formal contract defines terms and responsibilities.

This step officially launches the project.

Duration 2 weeks

Design & Engineering

Engineers create a modular plant design for your material.

Every solution is tailored to site conditions and capacity.

Duration up to 4 weeks

Manufacture & Delivery

Factory-built modules are produced under strict control.

All units are shipped fully prepared for assembly.

Duration 8 weeks

Assembly & Installation

On-site erection of modules and equipment setup.

Minimal impact on existing infrastructure.

Duration 24 weeks

Startup Control

Experts oversee plant startup and system calibration.

Every function is tested to ensure full performance.

Duration 10 weeks

Fine-Tuning

Process parameters are optimized for peak recovery.

Efficiency and stability are refined to perfection.

Duration 2 weeks

Operator Training

Hands-on instruction for operation and maintenance.

Your team gains full control and confidence.

Duration 4 weeks

Plant Handover

Final acceptance and performance verification.

The plant becomes a productive and certified asset.

Duration 1 week

Delivering a complete modular beneficiation plant in just 60 weeks is one of Gravicon’s strongest advantages. Our streamlined process — from testing to commissioning — allows clients to start production months earlier than competitors, achieving faster ROI and maintaining guaranteed performance standards.

12 monts

Average ROI period for modular plants in coal and gold applications

0,3ha

Minimal land footprint required per full-capacity processing unit

1,2kWh/ton

Energy efficiency for material processing in standard Gravicon configurations

24/7

Global support and remote monitoring for technical reliability